Table of Contents

ToggleIntroduction to EPP Foam and Its Growing Demand in India

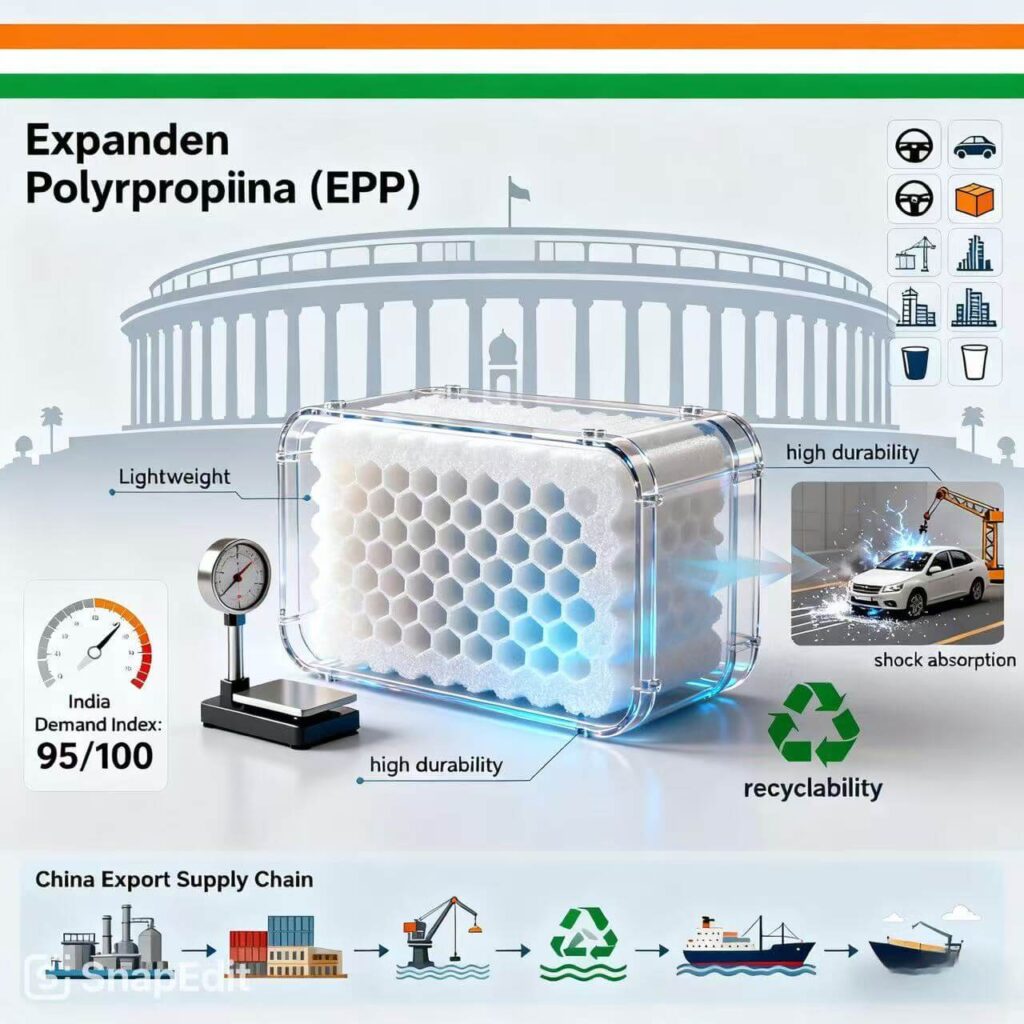

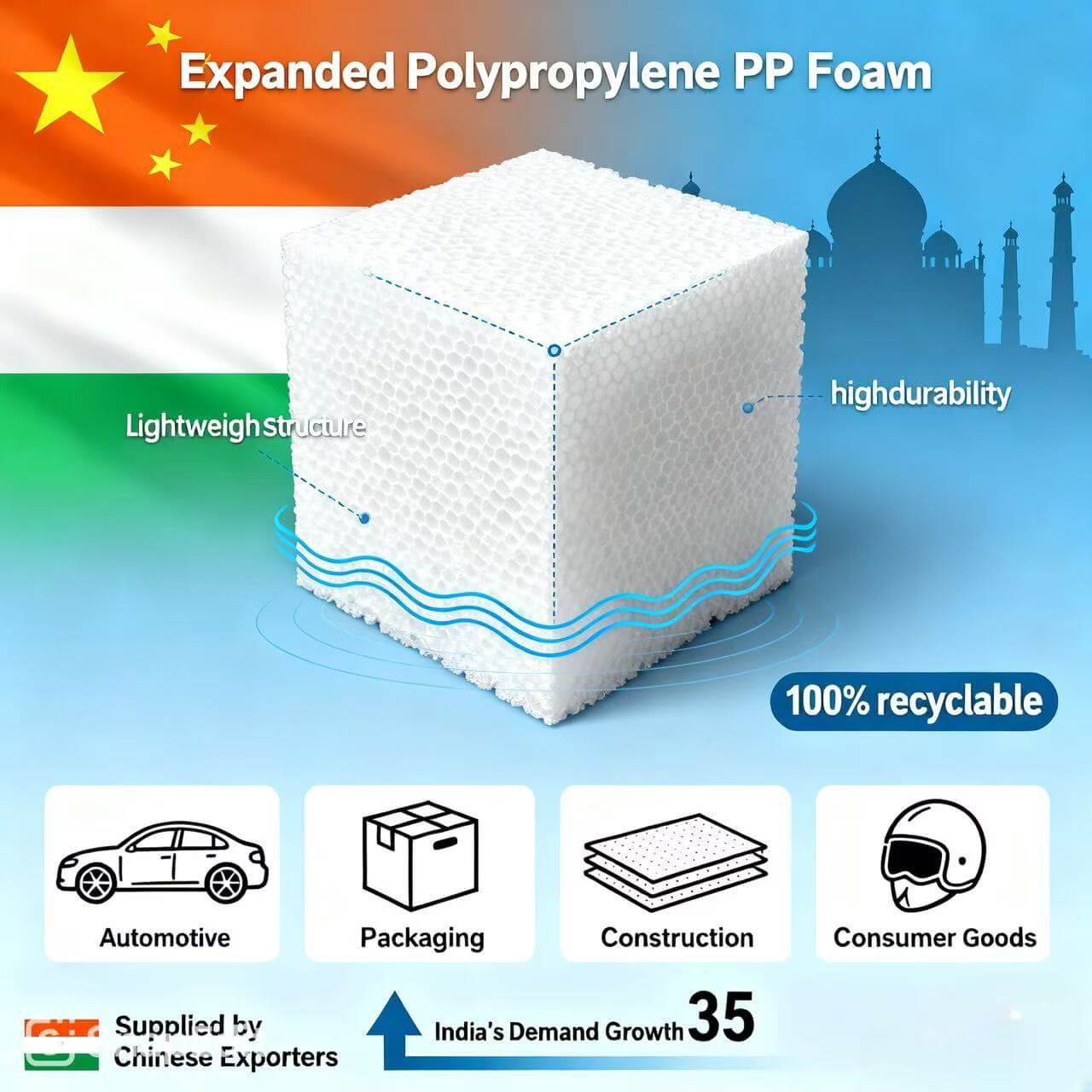

Expanded Polypropylene (EPP) foam has become one of the most versatile materials in modern industries. Known for its lightweight structure, high durability, shock absorption, and recyclability, EPP foam is widely used across the automotive, packaging, construction, and consumer goods sectors.

In recent years, India’s EPP foam demand has skyrocketed, driven by its expanding automotive industry, e-commerce packaging needs, and green building projects. As a result, many Indian buyers are searching for reliable EPP foam manufacturers in India—but increasingly, they turn to Chinese exporters for stable supply, better pricing, and advanced production capabilities.

Overview of the EPP Foam Market in India

Overview of the EPP Foam Market in India

Current Market Size and Growth Potential

India’s EPP foam market is valued at over USD 250 million and is expected to grow at a CAGR of 8–10% in the next five years. The demand comes mainly from automobile OEMs, logistics companies, and construction contractors.

Key Industries Driving EPP Foam Demand

- Automotive: Seat padding, crash absorption, bumpers.

- Packaging: Protective packaging for electronics and fragile goods.

- Construction: Insulation boards, energy-efficient buildings.

- Consumer Products: Sports equipment, household items, and toys.

Leading EPP Foam Manufacturers in India

Top Companies and Their Capabilities

Some well-known EPP foam manufacturers in India include:

- BASF India Ltd.

- JSP India Pvt. Ltd.

- Knauf Industries India

- Local mid-sized foam processing companies in Gujarat and Maharashtra

These companies mainly serve domestic markets, often working with automotive clients and packaging distributors.

Limitations of Local Manufacturing ⚠️

However, Indian EPP foam producers face challenges such as:

- Limited production capacity compared to China 🇨🇳

- Higher raw material costs 💰

- Inconsistent supply chain due to fluctuating demand 🔄

- Slower adoption of advanced molding technology 🛠️

China vs India: A Detailed Comparison

| Criteria | Indian Manufacturers 🇮🇳 | Chinese Manufacturers 🇨🇳 |

|---|---|---|

| Production Capacity | Medium-scale | Large-scale, mass production |

| Price Competitiveness | Higher costs 💰 | More affordable due to economies of scale ✅ |

| Technology | Limited automation ⚙️ | Advanced molding technology 🏭 |

| Export Capability | Limited focus on exports ❌ | Global export leader 🌏 |

| Lead Time | Longer delivery times ⏳ | Faster logistics & bulk shipping 🚚 |

Case Study: Chinese EPP Foam Export Success in India

Successful Partnerships in the Past Five Years 🤝

In the past five years, we have built strong partnerships with various industries. For example, we collaborated with PARK by supplying high-quality EPP beads for their projects, and we also worked closely with footwear manufacturers 👟 to provide lightweight yet resilient EPP foam materials.

Most importantly, we have successfully partnered with leading Indian automotive 🚗 and packaging 📦 companies. Our company alone has exported thousands of cubic meters of EPP foam blocks and molded EPP products to India, helping local businesses reduce costs by 15–20% while still meeting strict international quality standards 🌍✅.

Applications of EPP Foam in India

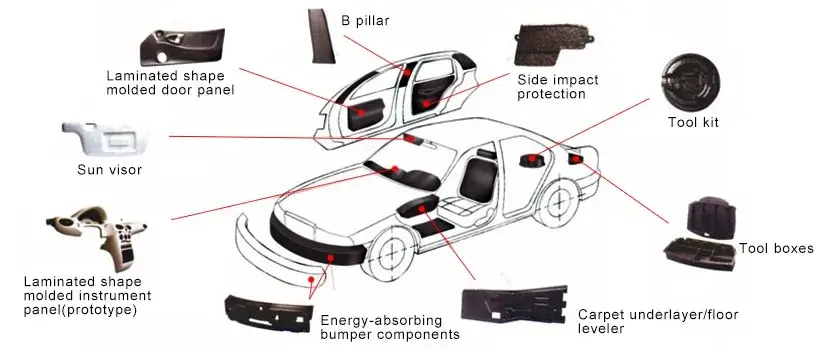

1. Automotive Industry

EPP foam is widely used in bumpers, seating, crash pads, and headrests due to its energy absorption properties. With India being the fourth-largest car manufacturer globally, the demand is huge.

2. Packaging Industry

E-commerce growth has created demand for protective packaging. EPP foam’s shock resistance makes it perfect for electronics, glassware, and medical equipment.

3. Construction & Insulation

Green building initiatives in India are pushing for lightweight insulation materials, where EPP foam plays a key role.

4. Consumer Goods & Electronics

From helmets to household appliances, EPP foam provides durability, safety, and lightweight design.

How to Choose the Best EPP Foam Manufacturer

Certifications and Quality Checks 🏅

Besides international standards, you can request free samples to test the EPP beads before placing bulk orders.

Production Capabilities 🏭

Look for manufacturers with high-volume capacity to meet the growing market demand efficiently.

Customization Options 🎨

Choose a manufacturer offering flexibility in custom molds, densities, and colors to match your specific requirements.

Why Partnering with a Chinese EPP Foam Manufacturer is the Best Option

Advantages of Importing from China 🌏

- Lower costs without compromising quality 💰✅

- Strong logistics networks 🚢📦

- Experience in handling large export orders 📑✈️

- Cutting-edge production technologies 🏭⚙️

FAQs on EPP Foam Manufacturers in India

Conclusion: The Future of EPP Foam Trade Between China and India

India’s booming automotive and packaging sectors are fueling a sharp rise in EPP foam demand…

👉 If you’re an Indian buyer searching for the best EPP foam manufacturers in India, the smartest decision is to import directly from China’s trusted suppliers.

Overview of the EPP Foam Market in India

Overview of the EPP Foam Market in India