EPP Beads Production Line

High-efficiency, Customizable, and Reliable

Introduction to EPP Beads Production Line

EPP (Expanded Polypropylene) beads are widely used in automotive, packaging, and consumer products due to their excellent strength-to-weight ratio and recyclability. At MOSO, we offer a complete EPP beads production line designed to deliver high-quality raw materials for your manufacturing needs.

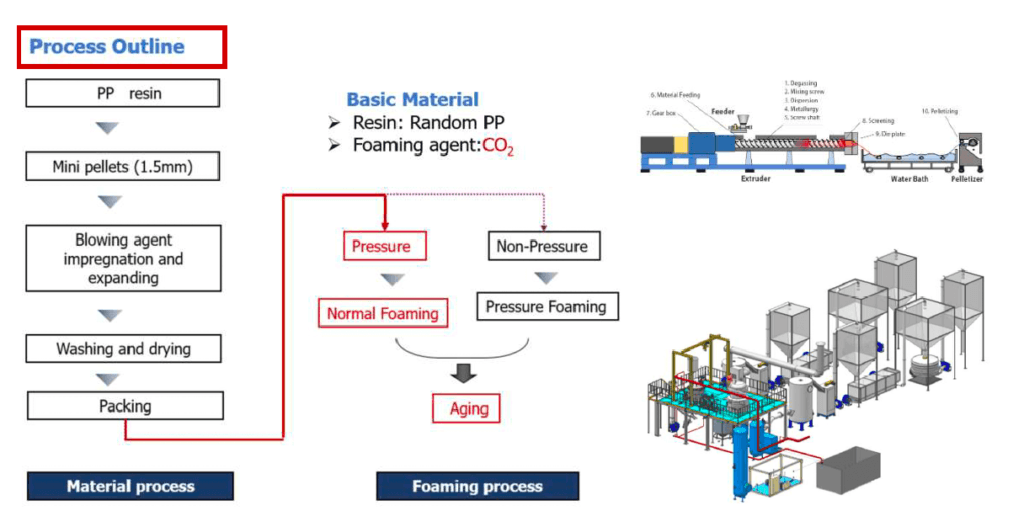

Complete Production Line Process

The EPP beads production line includes the following main stages:

Pre-expansion

Raw polypropylene is pre-heated with steam to form micro-cellular beads. This process determines the initial expansion ratio and foam characteristics.

Aging

Pre-expanded beads are stored in a pressure-stabilizing environment. This aging step allows the beads to release internal pressure and stabilize their structure for the next expansion phase.

Second Expansion

The aged beads are further expanded to achieve the desired final density. Steam pressure and time are adjusted precisely to meet different product specifications.

Drying and Sieving

After expansion, beads are dried to remove residual moisture. They are then sieved to classify them into uniform size ranges for consistent molding results.

Packaging

The final EPP beads are automatically packed in moisture-proof bags or containers, ready for shipment to molding factories or end users.

❤️❤️🔍 We can customize the production line to meet specific capacity and density requirements

❤️❤️🔍 The production line is used in our own factories

Applications of EPP Beads

EPP beads are used in automotive parts, packaging for shock absorption, construction insulation, and consumer products like containers and sports gear.

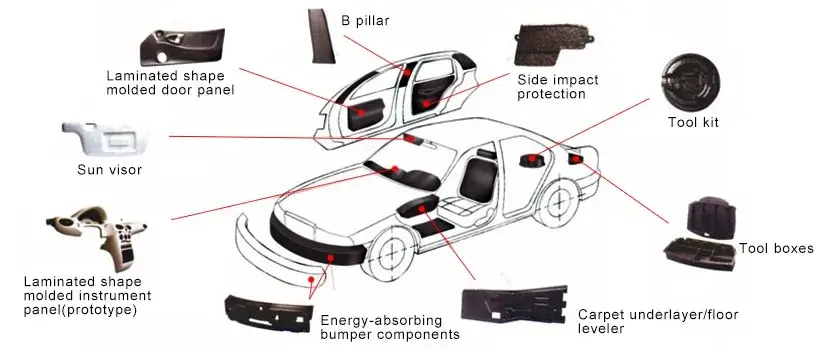

Automotive Industry

EPP beads are widely used in automotive components such as bumpers, seat cores, and interior panels for their lightweight and impact-resistant properties.

Packaging Industry

Perfect for creating protective packaging solutions, EPP beads provide shock absorption and durability during transportation.

Construction Industry

EPP beads are used in insulation panels and lightweight construction materials, offering excellent thermal insulation and energy efficiency.

Consumer Products

EPP beads are used in manufacturing items like sports equipment, furniture, and reusable containers due to their versatility and durability.

Key Features of Our EPP Beads Production Line

Advanced Technology

Our production lines are equipped with cutting-edge machinery that ensures precise bead size control, uniform expansion, and consistent quality.

Energy Efficiency

Designed with energy-saving systems, our production lines help reduce power consumption, lowering operational costs and environmental impact.

High Output Capacity

MOSO’s EPP beads production lines are capable of producing large volumes, meeting the demands of high-scale manufacturing industries.

Customization Options

We offer customizable production lines to suit your specific requirements, including bead sizes, densities, and production rates

Why Choose MOSO for Your EPP Beads Production Line?

Over 10 years of experience in EPP machinery

Professional technical support & installation service

Flexible customization options

Strong R&D capability to support OEM/ODM

MOSO’s EPP Beads Line

FAQ: About Moso epp beads production line

Yes, our machine supports adjustable steam pressure and expansion cycles.

From 300 kg/hour to 1000 kg/hour, depending on the configuration.

Yes, we provide full technical support both online and offline.

Contact Us to Learn More About Our EPP Beads Production Line

Want to build your own EPP bead production facility?

contact us for pricing, machine layout, and expert consultation.

MOSO EPP – Your Trusted Partner for High-Performance EPP Beads.