EPP Moulding Machine – Precision, Efficiency, and Durability

EPP Moulding Machine – Precision, Efficiency, and Durability

Discover our advanced EPP moulding machines, designed to deliver precise, efficient, and durable solutions for various industries, including automotive, packaging, and construction. With cutting-edge technology and customizable options, our machines ensure optimal performance and meet the highest quality standards.

EPP Moulding Machines for Exhibition Displays

EPP moulding machines are perfect for producing lightweight, durable exhibition displays and models. They ensure easy portability, high-quality finishes, and long-lasting performance, making them ideal for trade shows and promotional events.

Features of Our EPP Moulding Machines

1. High Precision and Efficiency

Our EPP moulding machines are engineered for precision moulding, ensuring consistent results with minimal material waste. The advanced controls optimize production efficiency.

2. Customizable Options

We offer customizable moulding machines to suit various production needs. From different mould sizes to adjustable settings, our machines can handle complex manufacturing requirements.

3. Energy-Saving Technology

Equipped with energy-efficient systems, our machines reduce power consumption while maintaining high performance. This makes them eco-friendly and cost-effective.

4. Durable and Long-Lasting Design

Built with high-quality materials, our moulding machines are designed to withstand long production cycles, ensuring reliability and low maintenance costs.

Benefits of Using EPP Moulding Machines

Investing in an EPP moulding machine provides numerous advantages:

- Lightweight Components: Produce lightweight yet durable foam products.

- Cost-Effective Production: Minimize material waste and energy costs.

- Eco-Friendly Manufacturing: Use recyclable EPP materials to promote sustainability.

- Versatile Applications: Suitable for industries like automotive, construction, and packaging.

Applications of EPP Moulding Machines

Applications of EPP Moulding Machines

Our EPP moulding machines are designed to cater to a wide range of industries:

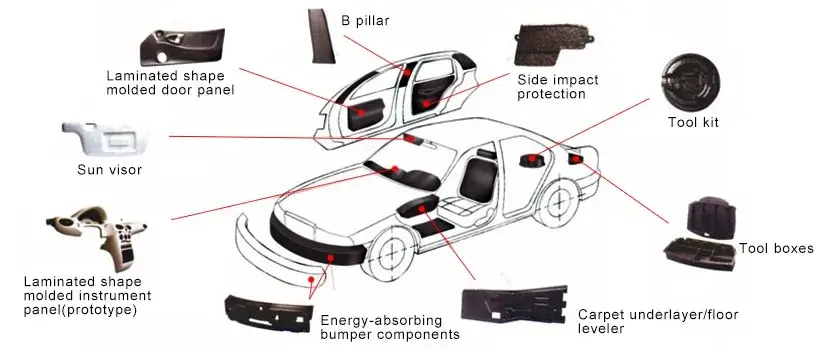

1. Automotive Industry

Used to create lightweight automotive parts like bumpers, headrests, and energy-absorbing components, improving vehicle fuel efficiency and safety.

2. Packaging Solutions

Produce protective packaging for electronics, fragile items, and industrial goods, ensuring products remain safe during transportation.

3. Construction Industry

Ideal for making thermal insulation panels and lightweight construction materials, contributing to energy-efficient buildings.

4. Electronics Protection

EPP moulding machines produce lightweight, durable casings that protect electronic devices from impacts, ensuring their safety during transport and use.

Why Choose Our EPP Moulding Machines?

At MOSO EPP, we pride ourselves on delivering high-quality moulding machines that exceed industry standards. Here’s why you should choose us:

- Industry Expertise: Years of experience in EPP manufacturing and technology.

- Advanced Technology: State-of-the-art machinery for superior performance.

- Reliable Support: Comprehensive after-sales support and maintenance services.

- Custom Solutions: Machines tailored to meet your unique production needs.

Contact Us for Your EPP Moulding Machine Needs

Ready to upgrade your production capabilities with our advanced EPP moulding machines? Contact us today to learn more about our products and services. Our team of experts is here to help you find the perfect solution for your business needs.

Wuxi Mosomec Technology Co., Ltd

Email:

info@mosomec.com

Phone/WA:

+86-137-7102-3986 (May)

+86-152-6157-5359(June)

MOSO EPP – Your Trusted Partner for High-Performance EPP Beads.

Applications of EPP Moulding Machines

Applications of EPP Moulding Machines